AI-9

Napreden, natančen in visokozmogljiv optični spajalnik

Inovativna 6-motorna tehnologija za natančno poravnavo jeder ter izredno hitro spajanje in gretje tulcev. AI-9 je najbolj kompletna naprava na tržišču ki je primerna tako za začetnike kot profesionalce.

Prevzem trenutno ni mogoč

Signalfire fiber splicer AI-9 is a six-motor, fiber core alignment automatic fiber welding machine, with optical power, red light detection function. Industrial quad-core CPU, fast running speed, 5 seconds fast welding, 15 seconds fast heating, 5 inches high resolution LCD screen, 300 times magnification; The working efficiency is 50% higher than that of ordinary welding machine. Large-capacity lithium battery can be heated by fusion of about 260 cores, high altitude, desert, extremely cold and other harsh environment performance is still outstanding.

Metal body with beautiful details

Fiber fusion splicer AI-9 is used in telecom, mobile, Unicom, radio and television operators, posts and telecommunications, railway engineering companies and institutions of optical cable line constriction, line maintenance, emerfency repair, security monitoring and research institutes research.

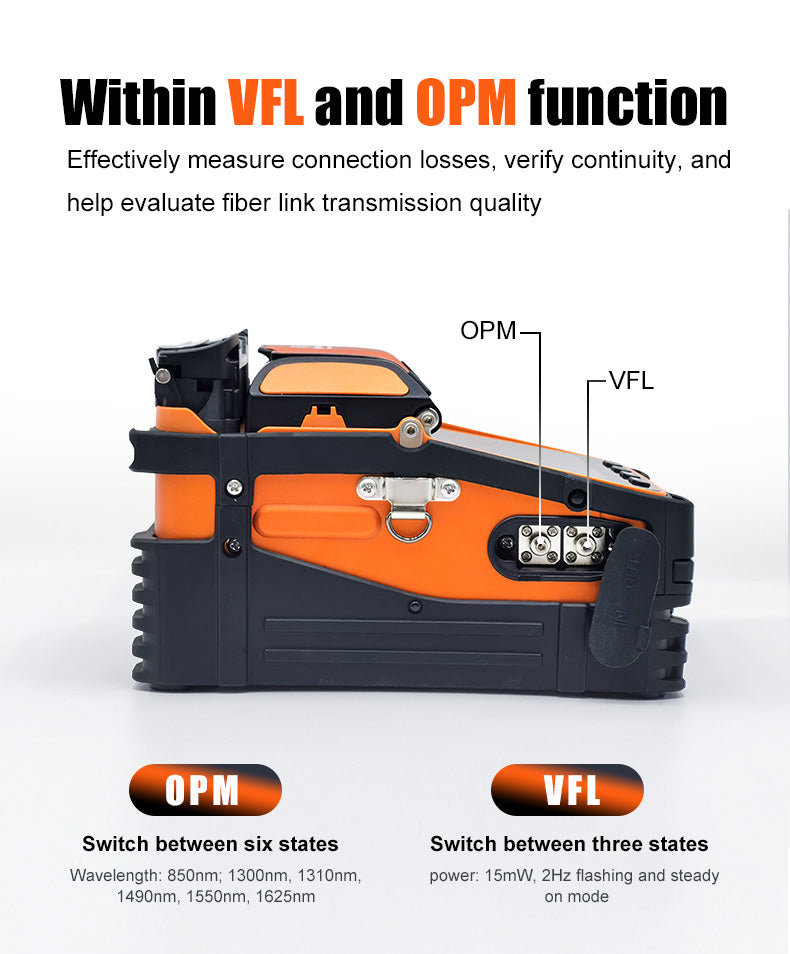

Within VFL and OPM function

Optical fusion splicer AI-9 effectively measure connection losses, vertidy continuity and help evaluate fiber ling transmission quality

Basic Parameters

| Fiber alignment | Core/cladding |

| Motor number | 6 motors |

| Splicing time | 5s |

| Heating mode | 15s, customizable based on the environment |

| Fiber type | Single-mode fiber (SMF/G.652), BIF/G.657; supports single mode, multi-mode, bare fiber, tail fiber, drop cable, jumper, invisible fiber fusion |

| The cladding diameter | 80–150μm |

| Splicing loss | 0.02dB (SM), 0.01dB (MM), 0.04dB (DS/NZDS) |

| Splicing mode | Automatic focusing core alignment, conventional/high-precision welding |

| Splicing way | Automatic, semi-automatic |

| Fiber holder | Three-in-one fixture, no need to change; suitable for single/multi-mode, multi-core cable, bare fiber, tail fiber, jumper fiber, drop cable |

| Fiber cleaver | High-precision delayed return electric one-step cleaver |

| VFL | 15mW power, 2Hz flashing or steady mode |

| OPM | Wavelengths: 850nm, 1300nm, 1310nm, 1490nm, 1550nm, 1625nm, 980nm, 1270nm, 1577nm, 1650nm Measurement range: -50~26dBm; Absolute error: <0.3dB (-50dBm ~ -3dBm range) |

| Battery capacity | 7800mAh large-capacity lithium battery, charges in 3.5h, can weld and heat approx. 260 cores |

| Magnification | 320× (X or Y axis single display), 200× (X and Y axis dual display) |

| Fiber diameter | Coating: 80–150μm / Cladding: 100–1000μm |

| Cutting length | 250μm coating: 8–16mm / 250–1000μm: 16mm |

| Heat shrink tube | 60mm, 50mm, 40mm, 25mm |

| Tensile testing | Standard 2N |

| Display | 5-inch TFT color display screen |

| Boot time | 15s to enter working mode |

| Data is stored | Unlimited, stores 1000 records, exports via USB |

| Wireless communication | Bluetooth 4.2, 2.4GHz band, range up to 60m |

| Software upgrade | Mobile phone APP supports internet upgrade |

| Management function | Manage records, logs, welding time, losses remotely; equipment can be bound to APP and used in batches |

| Return loss | Better than 60dB |

| Product protection | Waterproof, dustproof, drop-resistant |

| Power supply | AC100–240V 50/60Hz; output: DC13.5V/4.8A, real-time battery monitoring |

| The work environment | -15 ~ +50°C; humidity ≤95% (no condensation); altitude ≤5000m; max wind speed ≤15m/s |